- HOME

- PRODUCT

- NEWS

- ABOUT US

- CONTACT

Cut masonry nails production line machine list:

1.Payoff rack GO-300:1 set,(Payoff + Leveling)

2.Coiled belt steel feeding machine NCF-300:1 set (Feeder + electrical control system)

3.Blanking Pressing machine JG23-40A:1 set (Blanking + Nail embryo shank forming )

4.Pressing machine for nail head J23-25A:2 sets (Nail head pressing)

According to production capacity: 1 set blanking pressing machine JG23-40A coordinate with 2 sets nail head pressing machine J23-25A

Cut masonry nails production process:

1. According to the nail shape, customized coiled belt steel. ↓

2. Pressing the nail shank, automatic feeding the belt continuous stamping.↓

(Fit the coiled belt steel to the payoff rack, calibrate the flat material through the straightener, the automatic feeding by the feeder, blanking press JG23-40A punching profile, automatic continuous stamping)

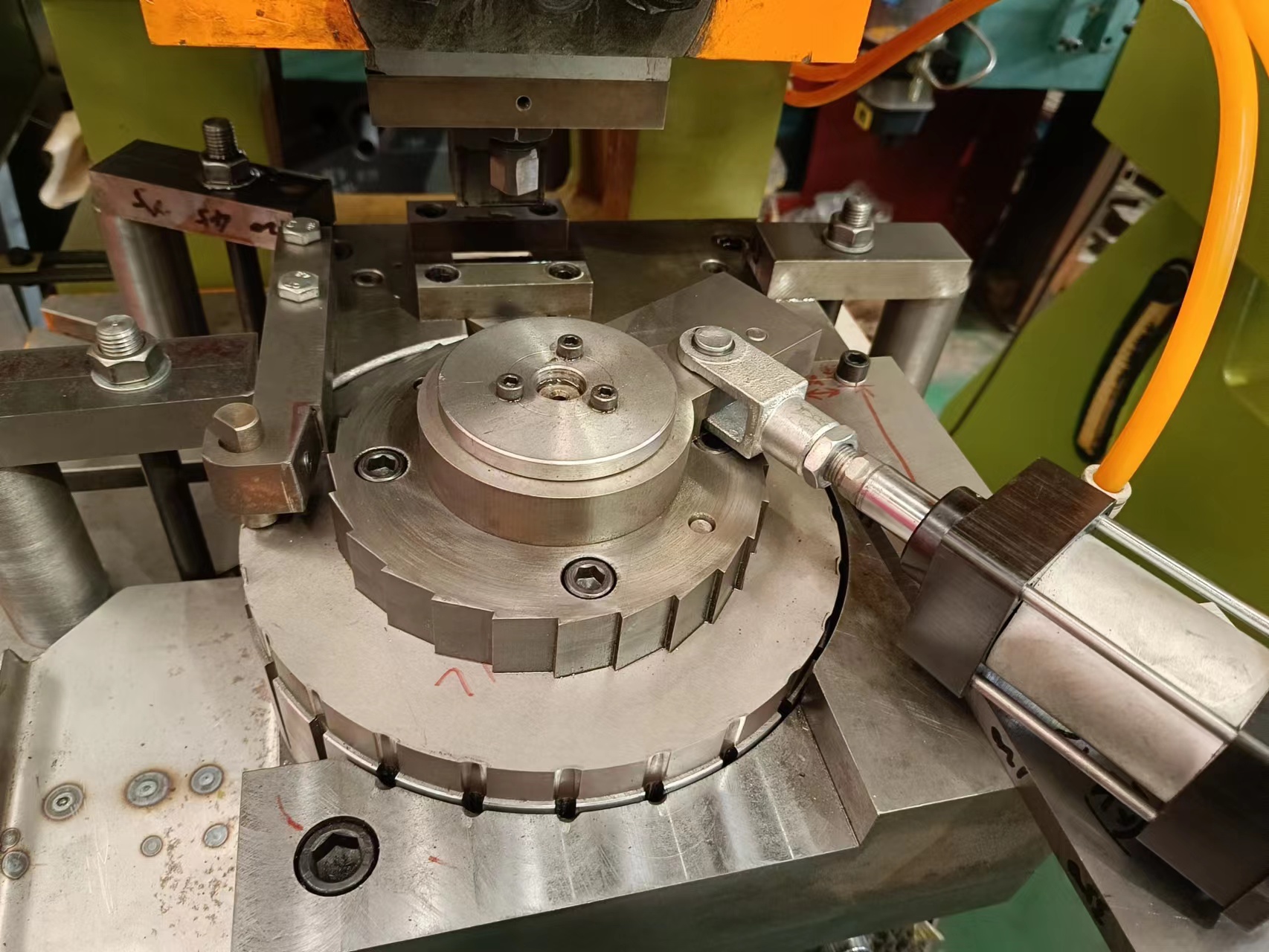

3. Masonry nail head forming.↓

(Manually place the pressed nail embryo into the J23-25A nail head pressing station die, and the mold is automatically rotated according to the pressing machine and stamping the nail heads one by one)

LOADING